Chemical vapor deposition (CVD) is a process which allows the creation of a deposit on the surface of mechanical parts, to protect them from oxidation and corrosion.

This protective coating is frequently used in aeronautics, especially on the reactors’ turbines blades which run at very high temperatures and in a very oxidizing atmosphere.

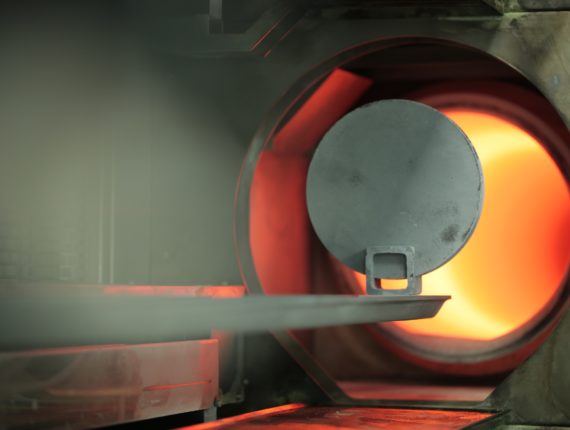

This process is usually realized at temperatures around 1000°C and 1150°C under neutral gas like Argon, and consists in creating a sealed enclosure on which mechanical parts are placed.

They are either manually made or in a totally automated way to optimize cycles.