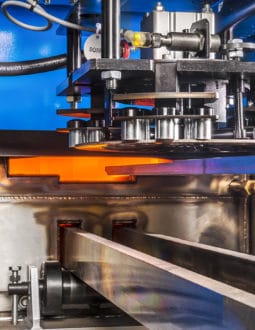

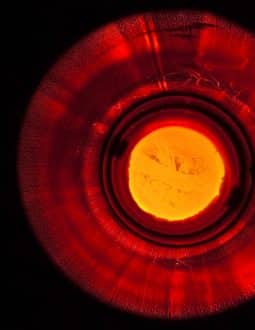

ECM Technologies forging furnaces are mainly dedicated to the heating process of ferrous alloys, heat-resistant super alloys, titanium alloys used in the aeronautics sector and specific alloys, used by the nuclear industry, that are transformed afterwards to their finished or semi-finished form by a press system.

Depending on your environment and constraints, different types of furnaces can be provided:

- Fixed hearth furnaces, composed of a casing and a fixed heat insulation where the loading is done via a front guillotine door.

- Rotary hearth furnaces, with a configuration that adapts to the needs

- Mobile hearth furnaces

- Pit furnaces

Our expertises come from the former company SERTHEL INDUSTRIE that is part of ECM since 2016.