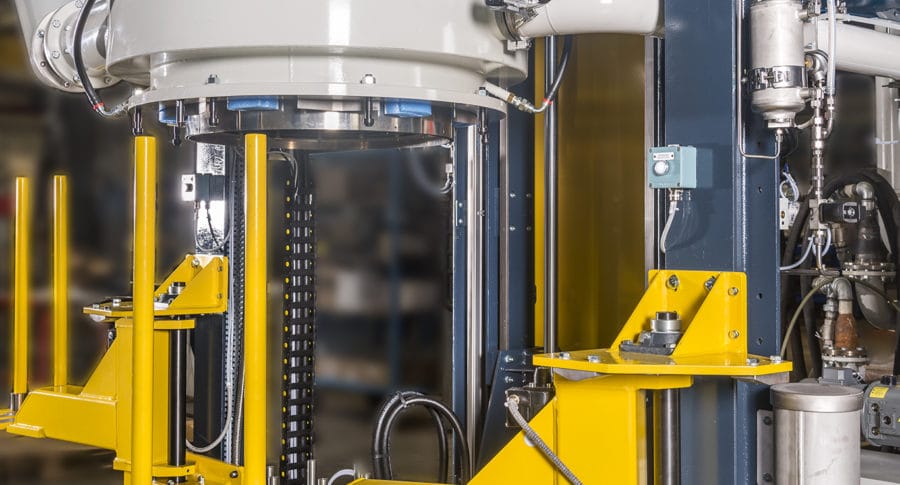

Diamant, hearth lift furnace is part of the ECM Technologies range of vacuum furnaces.

The possibility to choose the direction of the quench flow and its programming makes this furnace particularly suitable for cylindrical technical parts up to large dimensions. Its small size facilitates its integration on site.