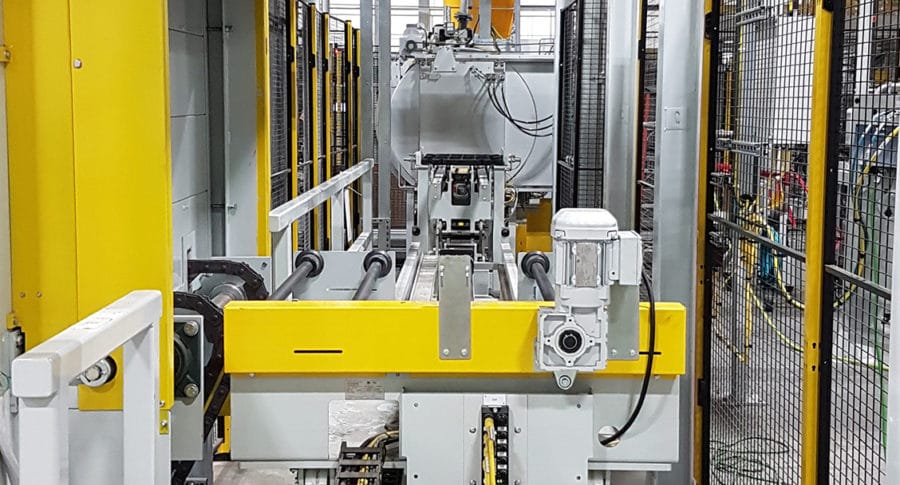

ICBP® JUMBO completes the low pressure / vacuum carburizing range of solutions which ECM Technologies proposes, enabling to process large loads at high frequency while offering an optimized access to all the components of the system.

The ICBP® Jumbo furnace keeps all of the compact and modular qualities of the ICBP® Flex, but goes further in terms of volume and number of parts treated in a low pressure carburizing installation.

Furthermore, the ICBP Jumbo system shows a high level of integration and automation. With, ECM Robotics ECM Technologies manages and integrates robots to optimize cycles before and after heat treatment operations.