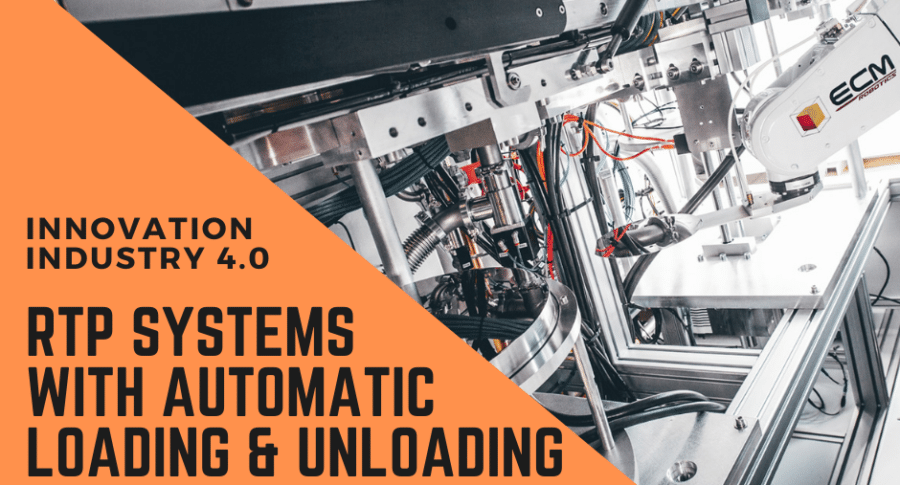

Robotized lines for rapid thermal processes

ECM Technologies has been recognized for several decades in the manufacturing of RTP vacuum furnaces for semiconductor applications. At the same time, it has also been able to expand its know-how in robotic integration for all kinds of applications, from handling various types of parts to the fitting out of robots, including tracking and vision systems.

A unique offer: furnaces + robots

All this know-how allows ECM Technologies to provide robotized installations, by mastering both the technical aspects specific to furnaces and their compatibility with robotized systems. This enables it to approach the entire project chain with reactivity and efficiency, from the equipment to its robotization, and to act as a single point of contact for its customers on increasingly complex projects.

This was recently the case during a consultation for a fully automated silicon wafer production line. This line is composed of two Jetfirst RTP furnaces, integrated in a robotic environment.

This collaborative solution has been developed for R&D applications in a clean environment. It allows cycles of 10 hours, freeing up time for process engineers in charge of these programs. Indeed, the robots are used to support these researchers to avoid certain repetitive tasks. This also guarantees increased process repeatability.

Expertise in heat treatment associated with robotics

After this first significant order, ECM Technologies is about to deliver a second line of the same type for a similar application. This first reference allows ECM Technologies to propose a new standardized offer for the supply of automated lines for rapid thermal processing: RTP, RTA, RTO, RTN.

On the other hand, the challenges related to the field of semiconductors, especially concerning the integration of furnaces and robots in clean environment have been mastered.

The on-line integration of this know-how opens new markets and allows ECM Technologies to reach a new milestone in Industry 4.0.