ECM Technologies, a key international actor in the field of vacuum carburizing, has extended its field of expertise to include new applications. Thanks to its recognized skills in heat, gas and atmosphere management, ECM Technologies masters many metallurgical processes within its ICBP systems.

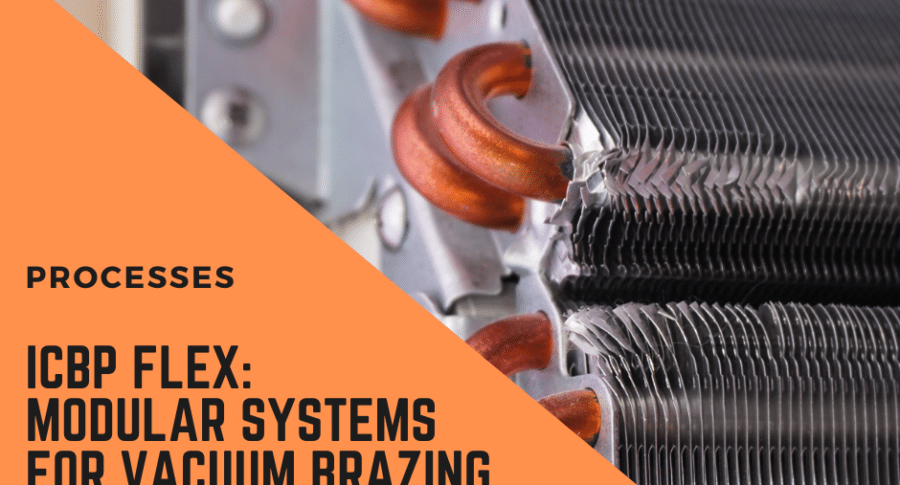

Brazing is a process which consists in joining two metallic items by melting a filler metal used as a joint, such as copper, cobalt or nickel. Performed at high temperature, vacuum brazing allows the assembly of simple or complex structures. It is a cost-effective process that can be easily integrated into the production of metal parts.

Vacuum brazing enabling high quality part production

ECM Technologies’ ICBP systems are modular and multi-process installations, which can handle vacuum brazing processes. This metallurgical process solves the issues encountered with atmospheric brazing. Temperature homogeneity and the absence of oxygen guarantee parts’ mechanical integrity and the absence of oxidation on parts assemblies.

Parts can be processed in batches, which allows an increased productivity and therefore more profitability. Brazing is thus opened to mass production within the ICBP; ECM Technologies previously mastered brazing for smaller series within its Cristal, Lilliput or Turquoise vacuum furnaces.

A technology adapted to a wide range of applications

The ECM Group has recently delivered two ICBP Flex installations for brazing applications. The first installation was delivered for the brazing of catalytic converters. This is a new Flex installation with brazing as the only treatment to be conducted. The second Flex installation is dedicated to the vacuum brazing of heat exchangers, which are used in many industries. In these two customer references, nickel-based and copper-based alloys are involved. Brazing is used more globally for the manufacturing of parts in aeronautics, automotive industry and electronics.

ECM Technologies’ systems can be completely automated with robotized loading and unloading steps. This guarantees a high quality for brazing applications. Indeed, it limits movements during parts’ solidification phases, limiting distortions and allowing a high uniformity and repeatability of the process.