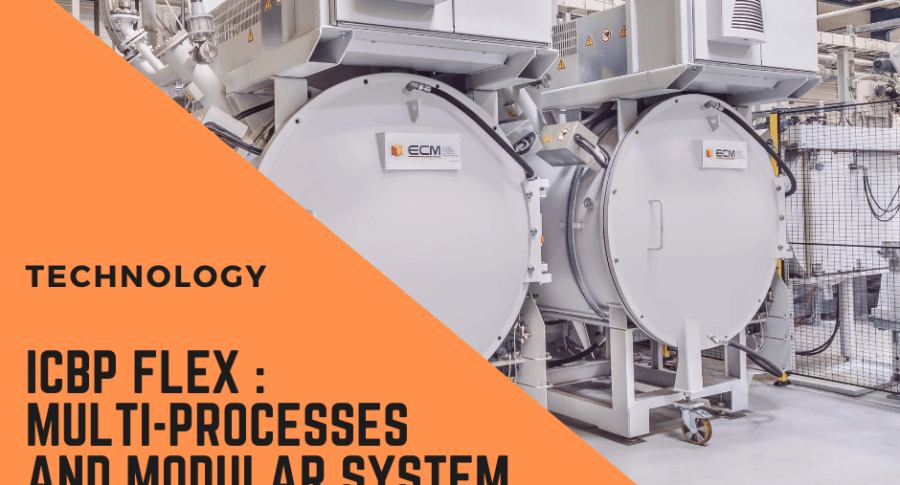

For nearly 40 years, ECM Technologies’ vacuum systems have been widely recognized in heat treatment and thermochemical process equipments. Firstly designed for vacuum carburizing, the ICBP Flex can now support a wide range of metallurgical processes. ICBP Flex systems have become modular furnaces and multi-processes installations.

New application perspectives

Thanks to its design based on a vacuum tunnel concept, the ICBP Flex can be adapted and tailored to perfectly match with customers’ technical requirements. Therefore, in addition to vacuum carburizing cells; vacuum brazing, tempering or nitriding chambers can be added on the same system. This flexibility widely helps to find the most efficient installation layout to meet the needs of the customers.

The modular and multi-process aspect allows the heat treatment of different materials and steel grades (alloys). Many temperatures levels are possible during the same cycle because each cell is independent to one another. These modular furnaces are particularly adapted to reach high productivity for different types of parts or to meet with the flexibility needs of commercial heat treatment workshops.

ECM technologies has recently commissioned an ICBP Flex system for mining applications. It is composed of several vacuum carburizing cells, a gas quenching cell, as well as nitriding and annealing cells on the same line. Pistons, ring cylinders and other parts made of different materials are treated at different temperatures. This greatly enhances productivity and ensures automated, clean and efficient cycles.

Towards 4.0 compliant modular furnaces

ECM Technologies recently supplied another ICBP Flex made of oxidation and brazing cells for the heat treatment of catalytic converters. This new installation is a proof of the teams’ ability to innovate and offer unique modular and multi-processes systems.

The development of ECM Robotics strengthens the Group’s offer. Thanks to its mastery of AGV/AMR technologies and its expertise in the integration of all types of robots, ECM is the unique contact for an automated, efficient and clean heat treatment line.