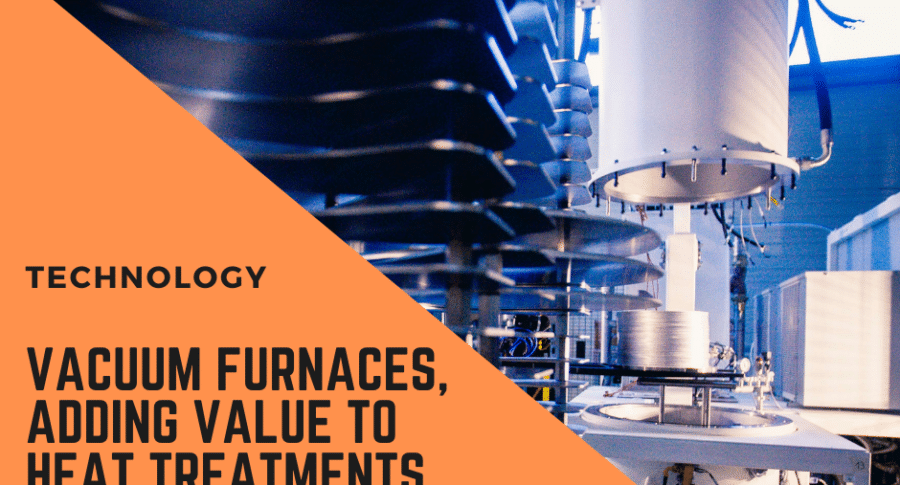

ECM Technologies has been developing and manufacturing vacuum furnaces for heat treatment since 1964. Thanks to its expertise in this field and strong investments in R&D, ECM Technologies has a complete product offering for a wide range of applications. The recent integration of companies such as Annealsys reinforces the ECM Group’s portfolio of applications and know-how, aiming at consolidating its project to develop innovative products and processes in the heat treatment industry.

The ECM Group has significant know-how in thermal processes such as sintering, brazing, tempering or annealing of various types of materials and alloys.

From laboratory applications to industrial vacuum heat treatment lines

The mastery of these numerous processes within our furnaces allows us to supply this equipment to various industries. The compact and robust design of ECM Technologies’ vacuum furnaces makes them particularly suitable to meet the needs of laboratories, research centers, institutes or universities. Looking for processes for high value-added parts, this range of furnaces is available in different formats to meet with the needs of each customer. The processes carried out in the Lilliput, Turquoise or Cristal ranges of vacuum furnaces guarantee efficient, high-quality treatments and the mechanical integrity of parts and assemblies sensitive to oxidation.

ECM Technologies’ vacuum furnaces are also adapted to larger production volumes requirements, such as in the automotive, aerospace, electronics and medical industries. This was recently the case with the supply of a large scale production line of ceramic parts issued from high temperature vacuum sintering. These parts are manipulated at high speed to build up loads before the sintering step – close to 3000 parts per load – and for the loading / unloading of the furnace – one from the Cristal range.

Heat treatment expertise associated to robotics

At the same time, the ECM Group has developed its skills in robotic integration, from handling all kinds of parts to the fitting of robots, as well as implementing tracking and vision systems, and more recently, mastering AGV & AMR technologies. All of this know-how allows ECM Technologies to provide turnkey, robotized and autonomous installations, while mastering both the technical aspects specific to furnaces and their integration in a robotized environment.